BLOG

Accelerating Change: The Impact of Mobile Applications on the Automotive Sector

The automotive industry is undergoing a significant transformation with smart manufacturing technologies. One of the key drivers of this revolution is the utilization of mobile applications in automotive assembly processes.

Mobile apps empower automobile companies to enhance productivity, streamline operations, and achieve greater efficiency on the assembly line.

In this blog post, we will explore how mobile apps are revolutionizing the automotive industry, and how they can optimize their manufacturing processes.

Understanding Smart Manufacturing in the Automotive Industry:

Smart manufacturing refers to automation, the Internet of Things (IoT), data analytics, and connectivity; that transform traditional manufacturing processes.

Smart manufacturing plays a crucial role in optimizing assembly operations, reducing costs, improving quality control, and enhancing overall efficiency.

Table of Content

- Flutter Vs React Native: Choosing The Right Framework For Your Mobile App

- Introduction To Flutter: Unleashing Cross-Platform App Development

- Mobile App Development Process: 10 Mistakes To Avoid

- Leveraging Mobile Apps For Precision Agriculture And Crop Monitoring

- Full-Stack: The Key To Building Scalable And Agile Businesses

- A Step-By-Step Guide To Mobile App Development Process: Part 1

- A Step-By-Step Guide To Mobile App Development Part 2

- Mobile App Development: Unlocking The Power Of Technology For The Modern World

- 14 Must-Have Features For A Successful Mobile App In 2023

- The Ultimate Guide To UI/UX Transformation And Its Benefits For Businesses

The Role of Mobile Applications in Automotive Assembly:

Mobile apps have revolutionized automotive assembly processes by providing real-time connectivity, seamless communication, and efficient data management.

These apps serve as a digital hub, enabling assembly line workers, supervisors, and managers to collaborate effectively, access critical information, and streamline workflows.

By integrating mobile applications with other smart manufacturing technologies, companies can achieve superior automation and synchronization

Key Features of Mobile Apps for Automotive Assembly:

Mobile apps designed specifically for automotive assembly processes encompass a range of key features that optimize efficiency and productivity. These features include:

Real-time Communication: Mobile apps facilitate instant communication among assembly line workers, supervisors, and managers, ensuring effective coordination and problem-solving.

Task Management:

Mobile applications enable the assignment and tracking of tasks, ensuring each assembly step is carried out in an organized manner.

Quality Control:

Mobile applications can integrate quality control checks and documentation. This allows real-time data collection, inspection, and traceability to ensure product quality and compliance.

Inventory Management:

Mobile apps can incorporate barcode scanning and QR code technology. It enables efficient tracking of parts and materials on the assembly line, reducing errors, and streamlining inventory management.

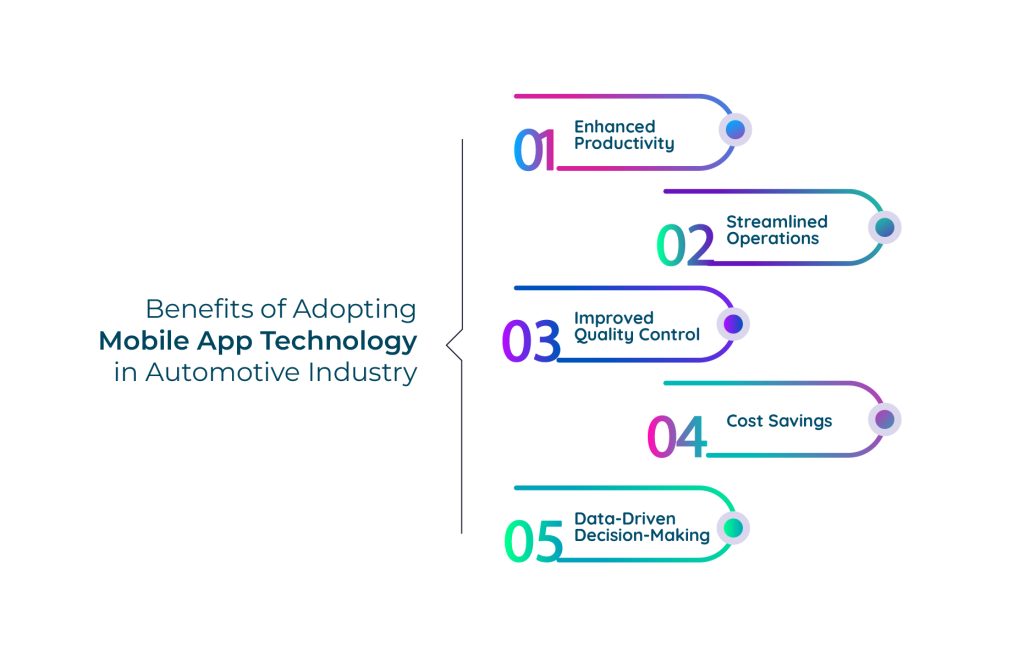

Benefits of Adopting Mobile Application Technology in the Automotive Industry:

The adoption of mobile apps in automotive assembly brings significant benefits to small and medium-sized automobile companies:

Enhanced Productivity:

Mobile apps optimize assembly line processes, eliminate manual paperwork, and reduce downtime, leading to increased productivity and faster production cycles.

Streamlined Operations:

Mobile apps streamline communication, facilitate real-time data sharing, and automate tasks, resulting in more efficient and synchronized assembly line operations.

Improved Quality Control:

Mobile apps enable real-time monitoring of quality parameters, ensuring adherence to quality standards, reducing defects, and enhancing overall product quality.

Cost Savings:

By reducing manual errors, improving inventory management, and optimizing workflows, mobile apps help reduce costs.

Data-Driven Decision-Making:

Mobile apps provide access to real-time production data, performance metrics, and analytics, enabling data-driven decision-making.

Things to consider before selecting Mobile Application Services:

When selecting a mobile app service provider for automotive assembly, consider this:

Functionality:

Ensure that the mobile app offers the necessary features and functionalities to support the specific requirements of automotive assembly processes. Like real-time communication, task management, and quality control.

Compatibility:

The mobile app should seamlessly integrate with existing manufacturing systems and equipment to enable smooth data exchange and workflow synchronization.

User Interface:

A user-friendly interface is crucial to ensure easy adoption and efficient utilization of the app by assembly line workers.

Data Security:

Mobile apps handling sensitive production data should provide robust security measures, including data encryption, access controls, and regular backups, to protect against unauthorized access and data breaches.

Scalability:

Consider whether the mobile app can scale with the growing needs of the automobile company, accommodating additional assembly lines, increased production volumes, and future technological advancements.

Technical Support:

Evaluate the level of technical support provided by the app service provider, including training, troubleshooting, and ongoing maintenance, to ensure smooth implementation and continued app performance.

How to implement the Digital Transformation to Mobile Apps:

The adoption of mobile apps in automotive assembly may present some challenges, including resistance to change, training needs, and integration complexities.

To overcome these challenges, consider the following strategies:

Change Management: Implement a comprehensive change management plan to communicate the benefits of mobile apps, address concerns, and encourage buy-in from assembly line workers and management.

Training and Education: Provide thorough training sessions to familiarize assembly line workers with the mobile app’s features, functionality, and benefits. Continuous education and support are essential for successful adoption.

Gradual Implementation: Start with pilot projects or specific assembly line areas to gradually introduce the mobile app and monitor its impact. This allows for learning, refinement, and identification of best practices before scaling up across the organization.

Collaboration and Knowledge-Sharing: Foster collaboration among automobile companies by participating in industry forums, sharing experiences, and exchanging insights on mobile app-based automotive assembly. Leveraging the collective knowledge of industry peers can accelerate adoption and enhance outcomes.

Future Trends to Look Forward in The Automotive Industry:

The future of mobile app-based automotive assembly holds exciting possibilities for small and medium-sized automobile companies. Some emerging trends to watch out for include:

Augmented Reality (AR) and Virtual Reality (VR): Integration of AR and VR technologies in mobile apps can enhance assembly line processes, facilitate remote training and troubleshooting, and enable interactive virtual simulations for efficient learning.

Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms can analyze assembly line data, identify patterns, and provide predictive insights for proactive maintenance, quality control, and process optimization.

Robotics and Automation: Mobile apps can integrate with robotics systems, allowing for seamless coordination and control of automated processes on the assembly line, resulting in increased efficiency and productivity.

Advanced Analytics and Big Data: Leveraging advanced analytics and big data technologies, mobile apps can provide real-time insights into production trends, performance metrics, and supply chain optimization, enabling data-driven decision-making and continuous improvement in automotive assembly processes.

The integration of mobile apps in automotive assembly processes is revolutionizing the way small and medium-sized automobile companies operate.

By leveraging the power of smart manufacturing, these companies can optimize their assembly lines, enhance productivity, streamline operations, and improve overall efficiency.

Mobile apps enable real-time communication, seamless data management, and task automation, empowering assembly line workers, supervisors, and managers to collaborate effectively and make data-driven decisions.

Looking ahead, the future automotive assembly holds exciting possibilities. This includes the integration of augmented reality, virtual reality, artificial intelligence, machine learning, robotics, and advanced analytics. Embracing these emerging technologies will further optimize assembly line processes, improve training and troubleshooting capabilities, and enable proactive maintenance and process optimization.

In conclusion, the integration of mobile apps in automotive assembly is transforming the industry, enabling automobile companies. It is helping them to embrace smart manufacturing, enhance productivity, and achieve greater efficiency on the assembly line. By leveraging mobile app-based solutions, these companies can stay competitive and drive sustainable growth in the years to come.

Related Topics

Trending Topics

Want to build Super app for your business?